Development

Development and construction of plastic parts following plastic technology rules. Assessing requirements according to DIN 69901/VDI 2591 and establishing specifications including a drawing.

- Taking into account thermal, mechanical, chemical and physical requirements

- Compliant with relevant regulation

- Use of 3D CAD and simulations with Moldflow

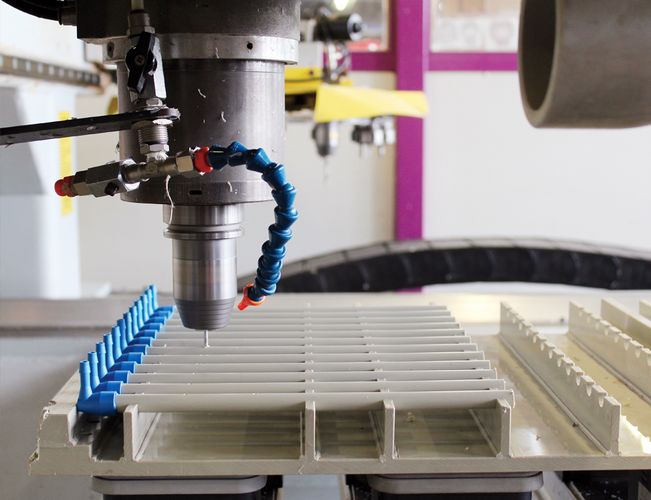

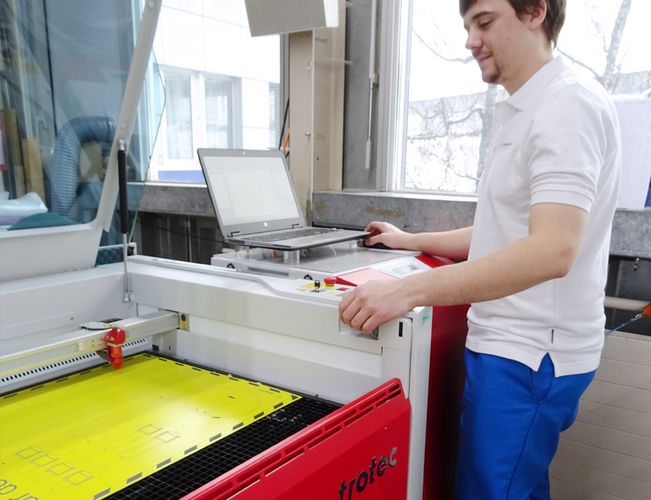

- Rapid Prototyping and Rapid Tooling

- Focus on safe processes and functional integration